|

|

|

|

Frame Build-Up Part VIII

|

|

A

Little Background.....My web hosting provider has seen fit to change the operating system not just once but twice, in the

last 4 months. While they claim they are introducing a new and much better system, the bottom line is they are simply changing

things up so that the many features that once were included as Standard Features, will now be Optional Features and you will

now have to pay for those Features. There new and better slogan, is really simply a farce, and what they want is more money

and more control over what you can do with there server space you rent.

I tell you this because there

are some notable differences to the site. While I have been very busy trying to keep this site up and running, functioning

as normal as can be expected, there have been times certain pages were unavailable. I have managed to circumvent many of there

road blocks with good old fashioned horse sense, and on occasion some pretty neat back door trickery. While they have certainly

cost me many hours of typing and re-typing, I have managed to keep all the functions I have had, with-out the extra cost to

play in and on there new site. Something tells me that sooner or latter they will catch-on to my tricks and figure out a way

to shut me down, or at least make me pay the new rate, but until then....here we are...and here we will stay.

|

|

|

Enter content here

Heres the passenger side view, you can see how the front down-bar conforms to the dash and also the cross-member that runs

under the dash and connects the two sides. The AC Unit is supported in the back by the firewall and in the friont by

the cross-brace, We built a simple get strong mount out of 3/4" square tubing, that bolts to the side of the AC-unit

to support it. The AC-Unit can be removed by removeing the bolts and lowering the unit straight down.

This like the previous pictures shows the AC-Unit and Passenger side roll bar. The form of the down bars is more evident

here, and you can also see the Bear Claw door stud we installed not so long ago. The latches work great, and I really

would recomend them to anyone wishing to up-grade there latches to better working, and much safer ones.

These

pictures all show different views of the roll cage, and body. You can see the wooden bows I metioned several times.

Like I said, I wished we could have gotten the roll bar a little closer fit to the wooden bows, but we had to leave room to

install them, and for the roof matterial and upolstry. The back Shelf will hold the battery, water tank and Sub Woofer

speaker. While the rear roll bar isn't perfect, it is much better then the rear hoop ideal we had.

The roll cage may be over-kill to some, and I would agree on many counts, but because of many things....like the fact the

car has a fabric roof, we will be making over 500 hourse-power and I would like to atleast try drag racing it some, I think

the roll cage is the right ideal. Yes it cuts down on interior room. Yes it takes a lot of time & Money to

construct. Yes it adds weight to the car. But it also adds a great measure of protection to the occupunts, really

strengthens the chasiss, and is used to support several major parts.

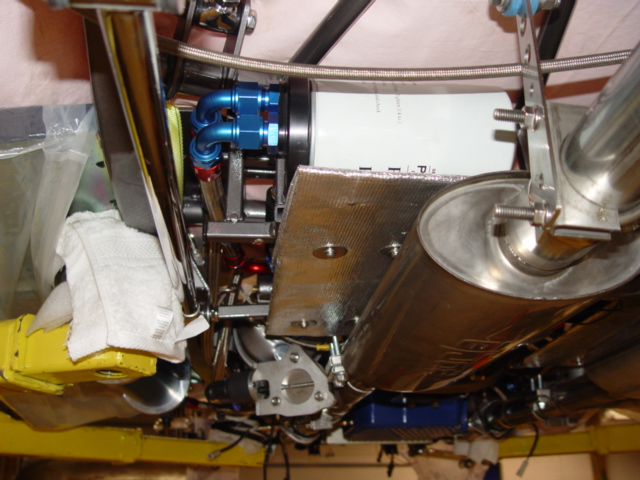

This

is a great shot of the drivers side rear frame view. You can see the remote oil filter and the heat-sheild we fabricated

to prevent the exhaust system from transfering heat to the oil filter. We addressed this issue several months ago, but

mainly we took a piece of 1/8" thick aluminum plate, added several layers of heat tape insulation (Header Warp) to both

sides, then covered it all with a sheet of reflective heat barrier(Termo-Tec). I have made other simular heat sheilds,

and all with very simular and succesful outcomes.

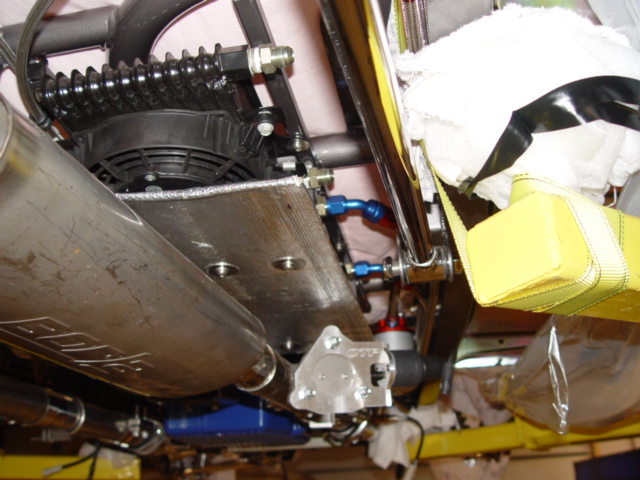

This

is the passenger side rear frame view. You can see the transmission cooler (it has the AN-8 lines attached) and the

inter-cooler cooler which is to the rear and does not have it's lines attached. Just below is the heat sheild we

made for this side, there is room between it's top and the coolers bottom to aid in air flow, but it will keep the

hot exhaust from seeping-up and into these two systems. Again all bolts/scres and fasteners are Stainless Steel on

Project'33

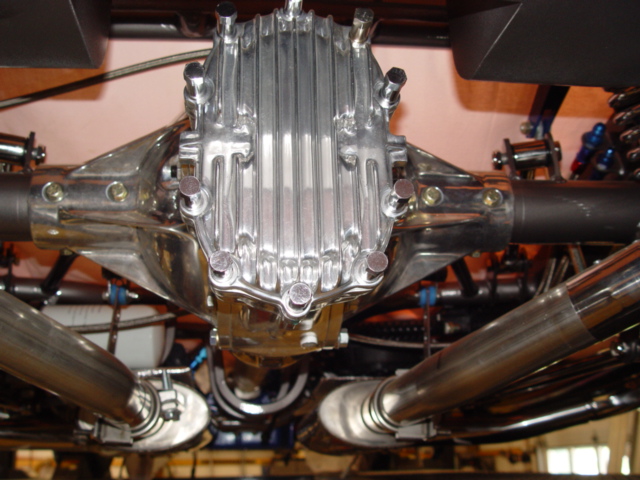

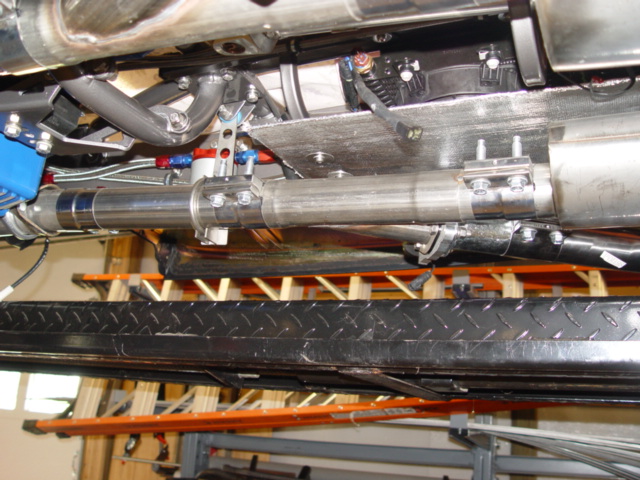

This

is our Accusump, from Canton. It is 3-quarts in size and I chose to use the billet aluminum mount to fasten it to the

bottom of the drivers side running board. The line feeding it is An-12 like the rest or the oiling system and it uses

a electric solinoid for for automatic control.

|

|

06-01-08

Before I moved the frame from the 2-Post lift to the 4-Post lift, where

it now rest, we did get a few things buttoned up. One such item was to re-route the oil lines from the engine adapter to the

oil filter and back to the cooler and accusump. While this was no big change, it was time consuming, I had to completely remove

the hoses and re-install them. The new installation, allowed for a better looking end product.

The hoses are now fully supports along there route and clamped

together with some very nice looking aluminum hose clamps, which keep the dressed side by side. The same goes for the other

side, I had to completely remove the transmission hoses and re-route them along the frame rail. Now the hoses look better

and fit the frame and space better, on both side I had to make adjustments to the length of several hoses. Keep this in mind

when you run your hoses. In hind sight, it would have been better

to completely leave the hoses alone, till the frame was completely ready for them, then run them one at a time along the frame rail from point "A" to point "B".

One great new item I finally got around to buying was a nice set of

cheater lenses for my welding hood. What a difference they make, way better they just wearing glasses under your hood, these

babies are crystal clear and I can now see. I am sure my welding will be much better from here on out, you can't weld

what you can't see!!!

I have been very busy around my house since

the first of the year, I decided to step a little further into the modular world, and build engines and cylinder heads for

others. I really fell in love with this engine and wanted to do more with it. I have been purchasing Teksid Aluminum blocks

and re-building them for re-sale to others. I have also decided to start re-building and modifying cylinder heads for the

modular engines. To help with the job, I purchased a valve seat grinder set-up and a valve face grinder set. This with several

other main tool sets will allow me to re-build and modify both 2, 3 and 4-valve heads. My goal is to simply offer great products

at fair prices, I am only concerned with the 4.6 and 5.4l engines and there heads. I have many neat ideals for these pieces

and have come up with several kits to make them stronger and easier to work on. You can read about them on this site by simply

clicking on the link that takes you to that part of the site.

06-02-08

We have been working on the dash, and the extended portion that spaces the front of the dash approximately 2-1/2" further

back then stock. I decided to add this section to the dash to allow us to install defrost ducts up next to the front window.

The benefits are obvious. Dad and I got the two new sections tach welded in place that spread the dash out. There are compound

type curves involved so the blanks took some time to get right, the welding was as usual, the easy part. The next step in

the dash dilemma, is to cap the ends and come up with a way to secure the two ends of the dash. I called the other day, and

dad has it worked out, just finishing up the fit.

Once the ends are capped, I want to get

started on the middle console. I have been thinking about it for some time, and once I get free to go down to the shop, I

can lay out all the pieces that go in the console and get it's final dimensions. We don't have tons of space, but

enough to do what I need done. The main point is to keep as much room between the console and seat fronts, and for the foot

area. No one wants to feel cramped in. Also, the design has to incorporate the theme of the car. I want it to look good and

be functional. We will also be designing and installing the roof console, that goes in the middle of the roof, from the front

windshield back about 12 inches. This console will house the rear view mirror and the overhead display.

Once the ends are capped, I want to get started on the middle console. I have been thinking about

it for some time, and once I get free to go down to the shop, I can lay out all the pieces that go in the console and get

it's final dimensions. We don't have tons of space, but enough to do what I need done. The main point is to keep as

much room between the console and seat fronts, and for the foot area. No one wants to feel cramped in. Also, the design has

to incorporate the theme of the car. I want it to look good and be functional. We will also be designing and installing the

roof console, that goes in the middle of the roof, from the front windshield back about 12 inches. This console will house

the rear view mirror and the overhead display.

Before I moved

the frame from the 2-Post lift to the 4-Post lift, where it now rest, we did get a few things buttoned up. One such item was

to re-route the oil lines from the engine adapter to the oil filter and back to the cooler and accusump. While this was no

big change, it was time consuming, I had to completely remove the hoses and re-install them. The new installation, allowed

for a better looking end product.

The hoses are now fully supports along there route and clamped together with some very nice looking aluminum hose clamps,

which keep the dressed side by side. The same goes for the other side, I had to completely remove the transmission hoses and

re-route them along the frame rail. Now the hoses look better and fit the frame and space better, on both side I had to make

adjustments to the length of several hoses. Keep this in mind when you run your hoses.

In hind sight, it would have been better to completely leave the hoses alone, till

the frame was completely ready for them, then run them one at a time along the

frame rail from point "A" to point "B".

One great

new item I finally got around to buying was a nice set of cheater lenses for my welding hood. What a difference they make,

way better they just wearing glasses under your hood, these babies are crystal clear and I can now see. I am sure my welding

will be much better from here on out, you can't weld what you can't see!!!

I have been very busy around my house since the first of the year, I decided to step a little further into the modular world,

and build engines and cylinder heads for others. I really fell in love with this engine and wanted to do more with it. I have

been purchasing Teksid Aluminum blocks and re-building them for re-sale to others. I have also decided to start re-building

and modifying cylinder heads for the modular engines. To help with the job, I purchased a valve seat grinder set-up and a

valve face grinder set. This with several other main tool sets will allow me to re-build and modify both 2, 3 and 4-valve

heads. My goal is to simply offer great products at fair prices, I am only concerned with the 4.6 and 5.4l engines and there

heads. I have many neat ideals for these pieces and have come up with several kits to make them stronger and easier to work

on. You can read about them on this site by simply clicking on the link that takes you to that part of the site.

06-02-08

We have been working on the dash, and the extended portion that

spaces the front of the dash approximately 2-1/2" further back then stock. I decided to add this section to the dash

to allow us to install defrost ducts up next to the front window. The benefits are obvious. Dad and I got the two new sections

tach welded in place that spread the dash out. There are compound type curves involved so the blanks took some time to get

right, the welding was as usual, the easy part. The next step in the dash dilemma, is to cap the ends and come up with a way

to secure the two ends of the dash. I called the other day, and dad has it worked out, just finishing up the fit.

Once the ends are capped, I want to get started on the middle console. I have been thinking about it for some time, and once

I get free to go down to the shop, I can lay out all the pieces that go in the console and get it's final dimensions.

We don't have tons of space, but enough to do what I need done. The main point is to keep as much room between the console

and seat fronts, and for the foot area. No one wants to feel cramped in. Also, the design has to incorporate the theme of

the car. I want it to look good and be functional. We will also be designing and installing the roof console, that goes in

the middle of the roof, from the front windshield back about 12 inches. This console will house the rear view mirror and the

overhead display.

Once the ends are capped, I want to get started on

the middle console. I have been thinking about it for some time, and once I get free to go down to the shop, I can lay out

all the pieces that go in the console and get it's final dimensions. We don't have tons of space, but enough to do

what I need done. The main point is to keep as much room between the console and seat fronts, and for the foot area. No one

wants to feel cramped in. Also, the design has to incorporate the theme of the car. I want it to look good and be functional.

We will also be designing and installing the roof console, that goes in the middle of the roof, from the front windshield

back about 12 inches. This console will house the rear view mirror and the overhead display.

Before I moved the frame from the 2-Post lift to the 4-Post lift, where

it now rest, we did get a few things buttoned up. One such item was to re-route the oil lines from the engine adapter to the

oil filter and back to the cooler and accusump. While this was no big change, it was time consuming, I had to completely remove

the hoses and re-install them. The new installation, allowed for a better looking end product. The hoses are now fully supports

along there route and clamped together with some very nice looking aluminum hose clamps, which keep the dressed side by side.

The same goes for the other side, I had to completely remove the transmission hoses and re-route them along the frame rail.

Now the hoses look better and fit the frame and space better, on both side I had to make adjustments to the length of several

hoses. Keep this in mind when you run your hoses. In hind sight, it would have been better to completely leave the hoses alone,

till the frame was completely ready for them, then run them one at a time along the frame rail from point "A" to

point "B".

One great new item I finally got around to buying was a nice set of cheater lenses

for my welding hood. What a difference they make, way better they just wearing glasses under your hood, these babies are crystal

clear and I can now see. I am sure my welding will be much better from here on out, you can't weld what you can't

see!!!

I have been very busy around my house since the first of the year,

I decided to step a little further into the modular world, and build engines and cylinder heads for others. I really fell

in love with this engine and wanted to do more with it. I have been purchasing Teksid Aluminum blocks and re-building them

for re-sale to others. I have also decided to start re-building and modifying cylinder heads for the modular engines. To help

with the job, I purchased a valve seat grinder set-up and a valve face grinder set. This with several other main tool sets

will allow me to re-build and modify both 2, 3 and 4-valve heads. My goal is to simply offer great products at fair prices,

I am only concerned with the 4.6 and 5.4l engines and there heads. I have many neat ideals for these pieces and have come

up with several kits to make them stronger and easier to work on. You can read about them on this site by simply clicking

on the link that takes you to that part of the site.

06-02-08

We have been working on the dash,

and the extended portion that spaces the front of the dash approximately 2-1/2" further back then stock. I decided to

add this section to the dash to allow us to install defrost ducts up next to the front window. The benefits are obvious. Dad

and I got the two new sections tach welded in place that spread the dash out. There are compound type curves involved so the

blanks took some time to get right, the welding was as usual, the easy part. The next step in the dash delama, is to cap the

ends and come up with a way to secure the two ends of the dash. I called the other day, and dad has it worked out, just finishing

up the fit.

Once the ends are capped, I want to get started on the middle

console. I have been thinking about it for some time, and once I get free to go down to the shop, I can lay out all the pieces

that go in the console and get it's final dimensions. We don't have tons of space, but enough to do what I need done.

The main point is to keep as much room between the console and seat fronts, and for the foot area. No one wants to feel cramped

in. Also, the design has to incorporate the theme of the car. I want it to look good and be functional. We will also be designing

and installing the roof console, that goes in the middle of the roof, from the front windshield back about 12 inches. This

console will house the rear view mirror and the overhead display.

06-10-08

Wow, I

have to get back into the spirit of working on the car, being away for a while like I was, makes you rusty.

The dash is all but finished, at least the modifications we made to it are. It turned out real nice, the section we installed

to widen it 2-1/2" looks nice, and Dad came up with a really cool way to cap off the ends and secure it. I removed it

and welded up the back side, just before we sanded down the front and removed 90% of the weld material. We had no warp-age

issues to address, which is good, and the whole thing was a positive experience. It looks right at home installed in the body,

but is different enough to draw attention, sound perfect to me !!.. One feature we worked hard on, was to make it easy to

install and uninstall from the body, and we were successful. Things get much more difficult with a roll cage to build around,

but it is possible to still make things right. It all just takes time and patients.

The defrost ducts, which were of coarse the reason we added the width to the dash, are in and went fine. We made the openings

much larger then those I have seen, most time others just cut a small 3/8" or 1/2" x 3" opening. I understand

why they do this, but it doesn't serve as a very good defrost duck with this small of an opening, so we cut an almost

full width and length opening in our dash, this way we will get plenty of flow and hopefully will be able to drive in the

rain. I am looking for some type of material to use as a screen, something like a heavy stainless steel material that is woven,

think HD screen or industrial sifter type material. I'll let you know when I find something. We have this option because

our dash is wider.

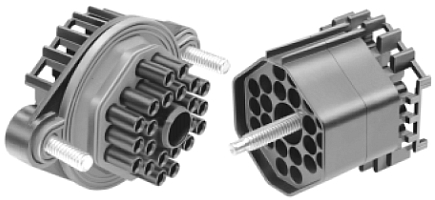

One item I got going was the door bars and seat back

bar. These items have to be removable, because they would severely limit the inside room and access, but are necessary for

competition. In order to make things as easy and nice as possible, I am using what is called a door bar kit. These items can

be purchased from most chassis builders and race shops, our came from S &W Race Cars and are unique in that they have

a center round tube that goes through the roll cage and gets welded in place. This tube serves as a stiffener and after welding,

replenishes the strength of the roll cage, were others simply leave a hole. The hole is there for the attachment to the roll

cage, so the door bars or rear seat back bar can be removed or installed quickly and easily, by simply installing a bolt or

quick release pin. This tube they sell with there door bar kits, serves to restore the integrity of the roll cage, where simply

drilling a 3/4" hole into the 1-5/8" tube would severely limit it's strength. I did modify our door bar kits

to accommodate our needs, the normal way to mount them would require a stub of the same diameter tubing be welded to the main

structure or roll cage. This stub which would have to be at least 3" in length, would serve as the foundation for the

door bar, but because I did not want anything sticking out from the roll cage that would limit or hinder front or rear seat

access, I modified the door bar kits, by drilling a relief in them so they would now fit over the existing roll cage and mount

without the stub. All that was needed was to drill with a hole saw, roughly the size of the roll cage material which in our

case is 1-5/8' tube, a relief in the edge of the door bar bracket so the new bracket will now wrap around the roll cage

bar instead of but up to it. To get this done, I had to tach weld the two pieces together, when drill a 1/4" pilot hole

in the right spot, when follow up with the hole saw. I'll post some pictures later to clarify the procedure. The benefit

of doing it like this is now the door bars and seat back bar will easily install and remove from the car and there is nothing

on the roll cage to snag or poke you as you enter or exist the car. These kits come in a package of two, with one push-pin

connector and one bolt and the four attachment halves. To do what we did would require three door bar kits, and they run about

$39.99 each kit. I have already ordered extra push-pins to eliminate the use of the bolts, now all the attachment will be

by push-pins, which will be much nicer to install and remove the bars.

Another small projects I worked on was to permanently attach the running boards. I had attached them with just a few bolts

to mock-up the Accusump oil sump, but now I need to go ahead and install all the hardware and bolt them up for good. First

I had to temporarily remove the Accusump to access the area. Next the running board metal braces we painted to match the frame

were installed, these I drilled out to accept a 3/8" bolt, and installed with all stainless steel hardware. They have

one 3/8" x 1" bolt that mount to the bottom of the frame, and then another 3/8" x 2" bolt that mounts

to the running boards, in a double sheer orientation that really adds some strength to the set-up. The rest of the running

board mounting bolts simply attach to the side of the frame, there are three bolts that support each brace and four bolts

that attach to the sides, that makes 14 3/8" bolts hold each running board on....I don't think their going any place!.!

I was simply amazed that everything aligned, I had been worried that there would be alignment issues but that wasn't even

an issue, they bolted right up, I only had to use a tapered alignment pin to bring everything together, wow what a great day!!!

Of-coarse I could not step on the newly installed running boards, but I did pull down on them and they seemed to be very stout.

I was worried because we had boxed the frame rails, and before I did that, I welded nuts to the back sides of the frame rails

so we could attached these running boards, the problem was there was no way to make-up for anything being off, not even a

little bit. We were locked into this location, and with the running boards being manufactured by one makers and the frame

by another, I was really worried about small differences that would add up against us. I can't tell you how relived I

was to see those running boards on and fitting like they should.

One little item I also got finished was I wrapped some

of the braided hoses that were close to the frame rails with a plastic wire loom material. I wanted to wrap them because braided

hose looks great and performed wonderfully, but they are very abrasive. While I have used hose separators and hose clamps

to keep the hose in place, there are still areas where the hose would rub the frame or other parts when driving, it's

these areas that I wrapped with the wire loom to keep from messing up the paint or other finish. I simply identified the problem

areas and then wrapped the hoses to protect the finishes from damage. You also want to avoid running wires along with hoses,

the abrasive hoses will eat right though the insulation on the wires allowing for a short circuit.

Back to the dash console......Wow this one item proved to be more difficult then I first thought.

My initial design was to make a spear like console, once I bent it up in the bender and compared it in the car, it was way

to big and interfered with the shifter and E brake handle. Design Number 2.....this time I made a more narrow and wider console,

I bent the pieces on the tube bender and assembled it on the bench, Oh..I am using 3/4" square tubing, 16 gauge for the

frame work on the console. This time I got the right dimensions but the initial mounting location was off. On to design Number

three...We removed the console and proceeded to change the mounting location to move it back further under the dash. We also

had to cut off part of the passenger side rear frame, to clear the Vintage Air AC unit. Now with the mounts located in the

very front, the console fit much better, there was way more knee room for the driver and the unit looked better tucked up

and back in under the dash. We used the under dash bar from the roll cage to mount the console, which also mounts the AC unit.

I welded on two tabs that hang down from the bottom of the bar to bolt to the sides of the console, which allow it to be removed

very easily. Now that we have a keeper, we marked out the face plate which was 1/8" flat sheet metal and cut it out and

trimmed it up to fit, then I drilled the mounting holes all seven of them and tapped the console for 10-32 mounting screws.

With the face plate looking great, we moved on to the outside skin of the console, here we used a piece of 20 gauge sheet

metal and formed it around the frame work of the console, tach welding it in place as we formed it. This was the quickest

part of the whole process, and in no time we had our console almost finished. We left plenty of material on each side, that

we will now trim off. This is where I left it, Dad will do the trimming latter on and we will also have to mark and trim the

openings in the face plate, but for now I'm leaving it bare. In all, I didn't quite get the room I wanted, but we

did get the console that best fits and matches the car, so I suppose that is the main thing. I have so many systems and Sub-systems

on this car that there just isn't enough room to properly mount all of them, or it doesn't seem that way now, maybe

things will change for the better as we get closer to the final product?.?.?

Project Cobra'33 is

really starting to come around, it won't be that long till we start in on the body work and paint preparations. From there,

we need to install the over head roll cage bars and console, then get the front seat mounted and in the proper place. Once

that is finished we can remove the front and rear halves of the roll cage and finish welding the front section. Remove the

seats and dash then go over the exterior of the body with our sand blaster and then apply a good base coat of epoxy primer,

and let the body work commence.

One great new item I finally got around to

buying was a nice set of cheater lenses for my welding hood. What a difference they make, way better they just wearing glasses

under your hood, these babies are crystal clear and I can now see. I am sure my welding will be much better from here on out,

you can't weld what you can't see!!!

I have been very busy around

my house since the first of the year, I decided to step a little further into the modular world, and build engines and cylinder

heads for others. I really fell in love with this engine and wanted to do more with it. I have been purchasing Teksid Aluminum

blocks and re-building them for re-sale to others. I have also decided to start re-building and modifying cylinder heads for

the modular engines. To help with the job, I purchased a valve seat grinder set-up and a valve face grinder set. This with

several other main tool sets will allow me to re-build and modify both 2, 3 and 4-valve heads. My goal is to simply offer

great products at fair prices, I am only concerned with the 4.6 and 5.4l engines and there heads. I have many neat ideals

for these pieces and have come up with several kits to make them stronger and easier to work on. You can read about them on

this site by simply clicking on the link that takes you to that part of the site.

06-02-08

We have been working on the dash, and the extended portion that spaces the front of the dash approximately 2-1/2" further

back then stock. I decided to add this section to the dash to allow us to install defrost ducts up next to the front window.

The benefits are obvious. Dad and I got the two new sections tach welded in place that spread the dash out. There are compound

type curves involved so the blanks took some time to get right, the welding was as usual, the easy part. The next step in

the dash delama, is to cap the ends and come up with a way to secure the two ends of the dash. I called the other day, and

dad has it worked out, just finishing up the fit.

Once the ends are capped,

I want to get started on the middle console. I have been thinking about it for some time, and once I get free to go down to

the shop, I can lay out all the pieces that go in the console and get it's final dimensions. We don't have tons of

space, but enough to do what I need done. The main point is to keep as much room between the console and seat fronts, and

for the foot area. No one wants to feel cramped in. Also, the design has to incorporate the theme of the car. I want it to

look good and be functional. We will also be designing and installing the roof console, that goes in the middle of the roof,

from the front windshield back about 12 inches. This console will house the rear view mirror and the overhead display.

06-10-08

Wow, I have to get back into the spirit of working on the car, being away for

a while like I was, makes you rusty.

The dash is all but finished, at least the modifications

we made to it are. It turned out real nice, the section we installed to widen it 2-1/2" looks nice, and Dad came up with

a really cool way to cap off the ends and secure it. I removed it and welded up the back side, just before we sanded down

the front and removed 90% of the weld material. We had no warp-age issues to address, which is good, and the whole thing was

a positive experience. It looks right at home installed in the body, but is different enough to draw attention, sound perfect

to me !!.. One feature we worked hard on, was to make it easy to install and uninstall from the body, and we were successful.

Things get much more difficult with a roll cage to build around, but it is possible to still make things right. It all just

takes time and patients.

The defrost ducts, which were of coarse the reason we

added the width to the dash, are in and went fine. We made the openings much larger then those I have seen, most time others

just cut a small 3/8" or 1/2" x 3" opening. I understand why they do this, but it doesn't serve as a very

good defrost duck with this small of an opening, so we cut an almost full width and length opening in our dash, this way we

will get plenty of flow and hopefully will be able to drive in the rain. I am looking for some type of material to use as

a screen, something like a heavy stainless steel material that is woven, think HD screen or industrial sifter type material.

I'll let you know when I find something. We have this option because our dash is wider.

One item I got going was the door bars and seat back bar. These items have to be removable, because they would severely limit

the inside room and access, but are necessary for competition. In order to make things as easy and nice as possible, I am

using what is called a door bar kit. These items can be purchased from most chassis builders and race shops, our came from

S &W Race Cars and are unique in that they have a center round tube that goes through the roll cage and gets welded in

place. This tube serves as a stiffener and after welding, replenishes the strength of the roll cage, were others simply leave

a hole. The hole is there for the attachment to the roll cage, so the door bars or rear seat back bar can be removed or installed

quickly and easily, by simply installing a bolt or quick release pin. This tube they sell with there door bar kits, serves

to restore the integrity of the roll cage, where simply drilling a 3/4" hole into the 1-5/8" tube would severely

limit it's strength. I did modify our door bar kits to accommodate our needs, the normal way to mount them would require

a stub of the same diameter tubing be welded to the main structure or roll cage. This stub which would have to be at least

3" in length, would serve as the foundation for the door bar, but because I did not want anything sticking out from the

roll cage that would limit or hinder front or rear seat access, I modified the door bar kits, by drilling a relief in them

so they would now fit over the existing roll cage and mount without the stub. All that was needed was to drill with a hole

saw, roughly the size of the roll cage material which in our case is 1-5/8' tube, a relief in the edge of the door bar

bracket so the new bracket will now wrap around the roll cage bar instead of but up to it. To get this done, I had to tach

weld the two pieces together, when drill a 1/4" pilot hole in the right spot, when follow up with the hole saw. I'll

post some pictures later to clarify the procedure. The benefit of doing it like this is now the door bars and seat back bar

will easily install and remove from the car and there is nothing on the roll cage to snag or poke you as you enter or exist

the car. These kits come in a package of two, with one push-pin connector and one bolt and the four attachment halves. To

do what we did would require three door bar kits, and they run about $39.99 each kit. I have already ordered extra push-pins

to eliminate the use of the bolts, now all the attachment will be by push-pins, which will be much nicer to install and remove

the bars.

Another small projects I worked on was to permanently

attach the running boards. I had attached them with just a few bolts to mock-up the Accusump oil sump, but now I need to go

ahead and install all the hardware and bolt them up for good. First I had to temporarily remove the Accusump to access the

area. Next the running board metal braces we painted to match the frame were installed, these I drilled out to accept a 3/8"

bolt, and installed with all stainless steel hardware. They have one 3/8" x 1" bolt that mount to the bottom of

the frame, and then another 3/8" x 2" bolt that mounts to the running boards, in a double sheer orientation that

really adds some strength to the set-up. The rest of the running board mounting bolts simply attach to the side of the frame,

there are three bolts that support each brace and four bolts that attach to the sides, that makes 14 3/8" bolts hold

each running board on....I don't think their going any place!.! I was simply amazed that everything aligned, I had been

worried that there would be alignment issues but that wasn't even an issue, they bolted right up, I only had to use a

tapered alignment pin to bring everything together, wow what a great day!!! Of-coarse I could not step on the newly installed

running boards, but I did pull down on them and they seemed to be very stout. I was worried because we had boxed the frame

rails, and before I did that, I welded nuts to the back sides of the frame rails so we could attached these running boards,

the problem was there was no way to make-up for anything being off, not even a little bit. We were locked into this location,

and with the running boards being manufactured by one makers and the frame by another, I was really worried about small differences

that would add up against us. I can't tell you how relived I was to see those running boards on and fitting like they

should.

One little item I also got finished was I wrapped some of the braided hoses that were close to the frame rails

with a plastic wire loom material. I wanted to wrap them because braided hose looks great and performed wonderfully, but they

are very abrasive. While I have used hose separators and hose clamps to keep the hose in place, there are still areas where

the hose would rub the frame or other parts when driving, it's these areas that I wrapped with the wire loom to keep from

messing up the paint or other finish. I simply identified the problem areas and then wrapped the hoses to protect the finishes

from damage. You also want to avoid running wires along with hoses, the abrasive hoses will eat right though the insulation

on the wires allowing for a short circuit.

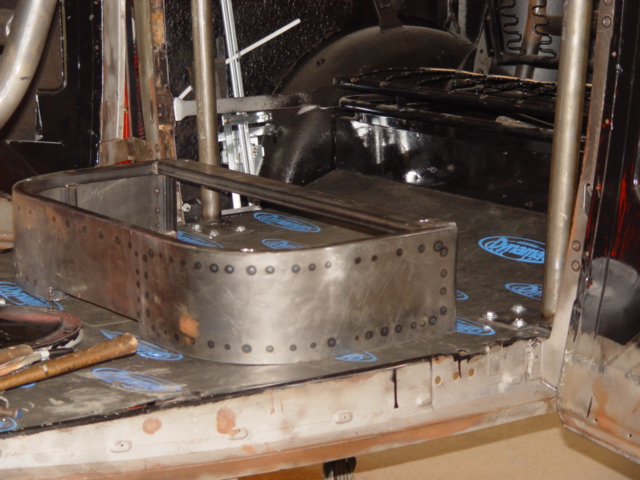

Back to the dash console......Wow

this one item proved to be more difficult then I first thought. My initial design was to make a spear like console, once I

bent it up in the bender and compared it in the car, it was way to big and interfered with the shifter and E brake handle.

Design Number 2.....this time I made a more narrow and wider console, I bent the pieces on the tube bender and assembled it

on the bench, Oh..I am using 3/4" square tubing, 16 gauge for the frame work on the console. This time I got the right

dimensions but the initial mounting location was off. On to design Number three...We removed the console and proceeded to

change the mounting location to move it back further under the dash. We also had to cut off part of the passenger side rear

frame, to clear the Vintage Air AC unit. Now with the mounts located in the very front, the console fit much better, there

was way more knee room for the driver and the unit looked better tucked up and back in under the dash. We used the under dash

bar from the roll cage to mount the console, which also mounts the AC unit. I welded on two tabs that hang down from the bottom

of the bar to bolt to the sides of the console, which allow it to be removed very easily. Now that we have a keeper, we marked

out the face plate which was 1/8" flat sheet metal and cut it out and trimmed it up to fit, then I drilled the mounting

holes all seven of them and tapped the console for 10-32 mounting screws. With the face plate looking great, we moved on to

the outside skin of the console, here we used a piece of 20 gauge sheet metal and formed it around the frame work of the console,

tach welding it in place as we formed it. This was the quickest part of the whole process, and in no time we had our console

almost finished. We left plenty of material on each side, that we will now trim off. This is where I left it, Dad will do

the trimming latter on and we will also have to mark and trim the openings in the face plate, but for now I'm leaving

it bare. In all, I didn't quite get the room I wanted, but we did get the console that best fits and matches the car,

so I suppose that is the main thing. I have so many systems and Sub-systems on this car that there just isn't enough room

to properly mount all of them, or it doesn't seem that way now, maybe things will change for the better as we get closer

to the final product?.?.?

Project

Cobra'33 is really starting

to come around, it won't be that long till we start in on the body work and paint preparations. From there, we need to

install the over head roll cage bars and console, then get the front seat mounted and in the proper place. Once that is finished

we can remove the front and rear halves of the roll cage and finish welding the front section. Remove the seats and dash then

go over the exterior of the body with our sand blaster and then apply a good base coat of epoxy primer, and let the body work

commence.

06-02-08

We have been working on the dash, and the extended portion that spaces the front of the dash approximately 2-1/2" further

back then stock. I decided to add this section to the dash to allow us to install defrost ducts up next to the front window.

The benefits are obvious. Dad and I got the two new sections tach welded in place that spread the dash out. There are compound

type curves involved so the blanks took some time to get right, the welding was as usual, the easy part. The next step in

the dash delama, is to cap the ends and come up with a way to secure the two ends of the dash. I called the other day, and

dad has it worked out, just finishing up the fit.

Once the ends are capped,

I want to get started on the middle console. I have been thinking about it for some time, and once I get free to go down to

the shop, I can lay out all the pieces that go in the console and get it's final dimensions. We don't have tons of

space, but enough to do what I need done. The main point is to keep as much room between the console and seat fronts, and

for the foot area. No one wants to feel cramped in. Also, the design has to incorporate the theme of the car. I want it to

look good and be functional. We will also be designing and installing the roof console, that goes in the middle of the roof,

from the front windshield back about 12 inches. This console will house the rear view mirror and the overhead display.

06-10-08

Wow, I have to get back into the spirit of working on the car, being away for

a while like I was, makes you rusty.

The dash is all but finished, at least the modifications

we made to it are. It turned out real nice, the section we installed to widen it 2-1/2" looks nice, and Dad came up with

a really cool way to cap off the ends and secure it. I removed it and welded up the back side, just before we sanded down

the front and removed 90% of the weld material. We had no warp-age issues to address, which is good, and the whole thing was

a positive experience. It looks right at home installed in the body, but is different enough to draw attention, sound perfect

to me !!.. One feature we worked hard on, was to make it easy to install and uninstall from the body, and we were successful.

Things get much more difficult with a roll cage to build around, but it is possible to still make things right. It all just

takes time and patients.

The defrost ducts, which were of coarse the reason we

added the width to the dash, are in and went fine. We made the openings much larger then those I have seen, most time others

just cut a small 3/8" or 1/2" x 3" opening. I understand why they do this, but it doesn't serve as a very

good defrost duck with this small of an opening, so we cut an almost full width and length opening in our dash, this way we

will get plenty of flow and hopefully will be able to drive in the rain. I am looking for some type of material to use as

a screen, something like a heavy stainless steel material that is woven, think HD screen or industrial sifter type material.

I'll let you know when I find something. We have this option because our dash is wider.

One item I got going was the door bars and seat back bar. These items have to be removable, because they would severely limit

the inside room and access, but are necessary for competition. In order to make things as easy and nice as possible, I am

using what is called a door bar kit. These items can be purchased from most chassis builders and race shops, our came from

S &W Race Cars and are unique in that they have a center round tube that goes through the roll cage and gets welded in

place. This tube serves as a stiffener and after welding, replenishes the strength of the roll cage, were others simply leave

a hole. The hole is there for the attachment to the roll cage, so the door bars or rear seat back bar can be removed or installed

quickly and easily, by simply installing a bolt or quick release pin. This tube they sell with there door bar kits, serves

to restore the integrity of the roll cage, where simply drilling a 3/4" hole into the 1-5/8" tube would severely

limit it's strength. I did modify our door bar kits to accommodate our needs, the normal way to mount them would require

a stub of the same diameter tubing be welded to the main structure or roll cage. This stub which would have to be at least

3" in length, would serve as the foundation for the door bar, but because I did not want anything sticking out from the

roll cage that would limit or hinder front or rear seat access, I modified the door bar kits, by drilling a relief in them

so they would now fit over the existing roll cage and mount without the stub. All that was needed was to drill with a hole

saw, roughly the size of the roll cage material which in our case is 1-5/8' tube, a relief in the edge of the door bar

bracket so the new bracket will now wrap around the roll cage bar instead of but up to it. To get this done, I had to tach

weld the two pieces together, when drill a 1/4" pilot hole in the right spot, when follow up with the hole saw. I'll

post some pictures later to clarify the procedure. The benefit of doing it like this is now the door bars and seat back bar

will easily install and remove from the car and there is nothing on the roll cage to snag or poke you as you enter or exist

the car. These kits come in a package of two, with one push-pin connector and one bolt and the four attachment halves. To

do what we did would require three door bar kits, and they run about $39.99 each kit. I have already ordered extra push-pins

to eliminate the use of the bolts, now all the attachment will be by push-pins, which will be much nicer to install and remove

the bars.

Another small projects I worked on was to permanently

attach the running boards. I had attached them with just a few bolts to mock-up the Accusump oil sump, but now I need to go

ahead and install all the hardware and bolt them up for good. First I had to temporarily remove the Accusump to access the

area. Next the running board metal braces we painted to match the frame were installed, these I drilled out to accept a 3/8"

bolt, and installed with all stainless steel hardware. They have one 3/8" x 1" bolt that mount to the bottom of

the frame, and then another 3/8" x 2" bolt that mounts to the running boards, in a double sheer orientation that

really adds some strength to the set-up. The rest of the running board mounting bolts simply attach to the side of the frame,

there are three bolts that support each brace and four bolts that attach to the sides, that makes 14 3/8" bolts hold

each running board on....I don't think their going any place!.! I was simply amazed that everything aligned, I had been

worried that there would be alignment issues but that wasn't even an issue, they bolted right up, I only had to use a

tapered alignment pin to bring everything together, wow what a great day!!! Of-coarse I could not step on the newly installed

running boards, but I did pull down on them and they seemed to be very stout. I was worried because we had boxed the frame

rails, and before I did that, I welded nuts to the back sides of the frame rails so we could attached these running boards,

the problem was there was no way to make-up for anything being off, not even a little bit. We were locked into this location,

and with the running boards being manufactured by one makers and the frame by another, I was really worried about small differences

that would add up against us. I can't tell you how relived I was to see those running boards on and fitting like they

should.

One little item I also got finished was I wrapped some of the braided hoses that were close to the frame rails

with a plastic wire loom material. I wanted to wrap them because braided hose looks great and performed wonderfully, but they

are very abrasive. While I have used hose separators and hose clamps to keep the hose in place, there are still areas where

the hose would rub the frame or other parts when driving, it's these areas that I wrapped with the wire loom to keep from

messing up the paint or other finish. I simply identified the problem areas and then wrapped the hoses to protect the finishes

from damage. You also want to avoid running wires along with hoses, the abrasive hoses will eat right though the insulation

on the wires allowing for a short circuit.

Back to the dash console......Wow

this one item proved to be more difficult then I first thought. My initial design was to make a spear like console, once I

bent it up in the bender and compared it in the car, it was way to big and interfered with the shifter and E brake handle.

Design Number 2.....this time I made a more narrow and wider console, I bent the pieces on the tube bender and assembled it

on the bench, Oh..I am using 3/4" square tubing, 16 gauge for the frame work on the console. This time I got the right

dimensions but the initial mounting location was off. On to design Number three...We removed the console and proceeded to

change the mounting location to move it back further under the dash. We also had to cut off part of the passenger side rear

frame, to clear the Vintage Air AC unit. Now with the mounts located in the very front, the console fit much better, there

was way more knee room for the driver and the unit looked better tucked up and back in under the dash. We used the under dash

bar from the roll cage to mount the console, which also mounts the AC unit. I welded on two tabs that hang down from the bottom

of the bar to bolt to the sides of the console, which allow it to be removed very easily. Now that we have a keeper, we marked

out the face plate which was 1/8" flat sheet metal and cut it out and trimmed it up to fit, then I drilled the mounting

holes all seven of them and tapped the console for 10-32 mounting screws. With the face plate looking great, we moved on to

the outside skin of the console, here we used a piece of 20 gauge sheet metal and formed it around the frame work of the console,

tach welding it in place as we formed it. This was the quickest part of the whole process, and in no time we had our console

almost finished. We left plenty of material on each side, that we will now trim off. This is where I left it, Dad will do

the trimming latter on and we will also have to mark and trim the openings in the face plate, but for now I'm leaving

it bare. In all, I didn't quite get the room I wanted, but we did get the console that best fits and matches the car,

so I suppose that is the main thing. I have so many systems and Sub-systems on this car that there just isn't enough room

to properly mount all of them, or it doesn't seem that way now, maybe things will change for the better as we get closer

to the final product?.?.?

Project

Cobra'33 is really starting

to come around, it won't be that long till we start in on the body work and paint preparations. From there, we need to

install the over head roll cage bars and console, then get the front seat mounted and in the proper place. Once that is finished

we can remove the front and rear halves of the roll cage and finish welding the front section. Remove the seats and dash then

go over the exterior of the body with our sand blaster and then apply a good base coat of epoxy primer, and let the body work

commence.

06-10-08

Wow, I have to get back into the spirit of

working on the car, being away for a while like I was, makes you rusty.

The dash is all but

finished, at least the modifications we made to it are. It turned out real nice, the section we installed to widen it 2-1/2"

looks nice, and Dad came up with a really cool way to cap off the ends and secure it. I removed it and welded up the back

side, just before we sanded down the front and removed 90% of the weld material. We had no warp-age issues to address, which

is good, and the whole thing was a positive experience. It looks right at home installed in the body, but is different enough

to draw attention, sound perfect to me !!.. One feature we worked hard on, was to make it easy to install and uninstall from

the body, and we were successful. Things get much more difficult with a roll cage to build around, but it is possible to still

make things right. It all just takes time and patients.

The defrost ducts, which

were of coarse the reason we added the width to the dash, are in and went fine. We made the openings much larger then those

I have seen, most time others just cut a small 3/8" or 1/2" x 3" opening. I understand why they do this, but

it doesn't serve as a very good defrost duck with this small of an opening, so we cut an almost full width and length

opening in our dash, this way we will get plenty of flow and hopefully will be able to drive in the rain. I am looking for

some type of material to use as a screen, something like a heavy stainless steel material that is woven, think HD screen or

industrial sifter type material. I'll let you know when I find something. We have this option because our dash is wider.

One item I got going was the door bars and seat back bar. These items have

to be removable, because they would severely limit the inside room and access, but are necessary for competition. In order

to make things as easy and nice as possible, I am using what is called a door bar kit. These items can be purchased from most

chassis builders and race shops, our came from S &W Race Cars and are unique in that they have a center round tube that

goes through the roll cage and gets welded in place. This tube serves as a stiffener and after welding, replenishes the strength

of the roll cage, were others simply leave a hole. The hole is there for the attachment to the roll cage, so the door bars

or rear seat back bar can be removed or installed quickly and easily, by simply installing a bolt or quick release pin. This

tube they sell with there door bar kits, serves to restore the integrity of the roll cage, where simply drilling a 3/4"

hole into the 1-5/8" tube would severely limit it's strength. I did modify our door bar kits to accommodate our needs,

the normal way to mount them would require a stub of the same diameter tubing be welded to the main structure or roll cage.

This stub which would have to be at least 3" in length, would serve as the foundation for the door bar, but because I

did not want anything sticking out from the roll cage that would limit or hinder front or rear seat access, I modified the

door bar kits, by drilling a relief in them so they would now fit over the existing roll cage and mount without the stub.

All that was needed was to drill with a hole saw, roughly the size of the roll cage material which in our case is 1-5/8'

tube, a relief in the edge of the door bar bracket so the new bracket will now wrap around the roll cage bar instead of but

up to it. To get this done, I had to tach weld the two pieces together, when drill a 1/4" pilot hole in the right spot,

when follow up with the hole saw. I'll post some pictures later to clarify the procedure. The benefit of doing it like

this is now the door bars and seat back bar will easily install and remove from the car and there is nothing on the roll cage

to snag or poke you as you enter or exist the car. These kits come in a package of two, with one push-pin connector and one

bolt and the four attachment halves. To do what we did would require three door bar kits, and they run about $39.99 each kit.

I have already ordered extra push-pins to eliminate the use of the bolts, now all the attachment will be by push-pins, which

will be much nicer to install and remove the bars.

Another

small projects I worked on was to permanently attach the running boards. I had attached them with just a few bolts to mock-up

the Accusump oil sump, but now I need to go ahead and install all the hardware and bolt them up for good. First I had to temporarily

remove the Accusump to access the area. Next the running board metal braces we painted to match the frame were installed,

these I drilled out to accept a 3/8" bolt, and installed with all stainless steel hardware. They have one 3/8" x

1" bolt that mount to the bottom of the frame, and then another 3/8" x 2" bolt that mounts to the running boards,

in a double sheer orientation that really adds some strength to the set-up. The rest of the running board mounting bolts simply

attach to the side of the frame, there are three bolts that support each brace and four bolts that attach to the sides, that

makes 14 3/8" bolts hold each running board on....I don't think their going any place!.! I was simply amazed that

everything aligned, I had been worried that there would be alignment issues but that wasn't even an issue, they bolted

right up, I only had to use a tapered alignment pin to bring everything together, wow what a great day!!! Of-coarse I could

not step on the newly installed running boards, but I did pull down on them and they seemed to be very stout. I was worried

because we had boxed the frame rails, and before I did that, I welded nuts to the back sides of the frame rails so we could

attached these running boards, the problem was there was no way to make-up for anything being off, not even a little bit.

We were locked into this location, and with the running boards being manufactured by one makers and the frame by another,

I was really worried about small differences that would add up against us. I can't tell you how relived I was to see those

running boards on and fitting like they should.

One little item I also got finished was I wrapped some of the braided

hoses that were close to the frame rails with a plastic wire loom material. I wanted to wrap them because braided hose looks

great and performed wonderfully, but they are very abrasive. While I have used hose separators and hose clamps to keep the

hose in place, there are still areas where the hose would rub the frame or other parts when driving, it's these areas

that I wrapped with the wire loom to keep from messing up the paint or other finish. I simply identified the problem areas

and then wrapped the hoses to protect the finishes from damage. You also want to avoid running wires along with hoses, the

abrasive hoses will eat right though the insulation on the wires allowing for a short circuit.

Back to the dash console......Wow this one item proved to be more difficult then I first thought. My initial design was to

make a spear like console, once I bent it up in the bender and compared it in the car, it was way to big and interfered with

the shifter and E brake handle. Design Number 2.....this time I made a more narrow and wider console, I bent the pieces on

the tube bender and assembled it on the bench, Oh..I am using 3/4" square tubing, 16 gauge for the frame work on the

console. This time I got the right dimensions but the initial mounting location was off. On to design Number three...We removed

the console and proceeded to change the mounting location to move it back further under the dash. We also had to cut off part

of the passenger side rear frame, to clear the Vintage Air AC unit. Now with the mounts located in the very front, the console

fit much better, there was way more knee room for the driver and the unit looked better tucked up and back in under the dash.

We used the under dash bar from the roll cage to mount the console, which also mounts the AC unit. I welded on two tabs that

hang down from the bottom of the bar to bolt to the sides of the console, which allow it to be removed very easily. Now that

we have a keeper, we marked out the face plate which was 1/8" flat sheet metal and cut it out and trimmed it up to fit,

then I drilled the mounting holes all seven of them and tapped the console for 10-32 mounting screws. With the face plate

looking great, we moved on to the outside skin of the console, here we used a piece of 20 gauge sheet metal and formed it

around the frame work of the console, tach welding it in place as we formed it. This was the quickest part of the whole process,

and in no time we had our console almost finished. We left plenty of material on each side, that we will now trim off. This

is where I left it, Dad will do the trimming latter on and we will also have to mark and trim the openings in the face plate,

but for now I'm leaving it bare. In all, I didn't quite get the room I wanted, but we did get the console that best

fits and matches the car, so I suppose that is the main thing. I have so many systems and Sub-systems on this car that there

just isn't enough room to properly mount all of them, or it doesn't seem that way now, maybe things will change for

the better as we get closer to the final product?.?.?

Project Cobra'33 is

really starting to come around, it won't be that long till we start in on the body work and paint preparations. From there,

we need to install the over head roll cage bars and console, then get the front seat mounted and in the proper place. Once

that is finished we can remove the front and rear halves of the roll cage and finish welding the front section. Remove the

seats and dash then go over the exterior of the body with our sand blaster and then apply a good base coat of epoxy primer,

and let the body work commence.

Project

Cobra'33 is really starting

to come around, it won't be that long till we start in on the body work and paint preparations. From there, we need to

install the over head roll cage bars and console, then get the front seat mounted and in the proper place. Once that is finished

we can remove the front and rear halves of the roll cage and finish welding the front section. Remove the seats and dash then

go over the exterior of the body with our sand blaster and then apply a good base coat of epoxy primer, and let the body work

commence.

One great new item I finally got around to buying was a nice set of cheater lenses for my

welding hood. What a difference they make, way better they just wearing glasses under your hood, these babies are crystal

clear and I can now see. I am sure my welding will be much better from here on out, you can't weld what you can't

see!!!

I have been very busy around my house since the first of the

year, I decided to step a little further into the modular world, and build engines and cylinder heads for others. I really

fell in love

with this engine and wanted to do more with it. I have been purchasing Teksid Aluminum blocks and re-building them for re-sale

to others. I have also decided to start re-building and modifying cylinder heads for the modular engines. To help with the

job, I purchased a valve seat grinder set-up and a valve face grinder set. This with several other main tool sets will allow

me to re-build and modify both 2, 3 and 4-valve heads. My goal is to simply offer great products at fair prices, I am only

concerned with the 4.6 and 5.4l engines and there heads. I have many neat ideals for these pieces and have come up with several

kits to make them stronger and easier to work on. You can read about them on this site by simply clicking on the link that

takes you to that part of the site.

06-02-08

We have been working on the dash, and the extended portion that spaces the front of the dash approximately 2-1/2" further

back then stock. I decided to add this section to the dash to allow us to install defrost ducts up next to the front window.

The benefits are obvious. Dad and I got the two new sections tach welded in place that spread the dash out. There are compound

type curves involved so the blanks took some time to get right, the welding was as usual, the easy part. The next step in

the dash delama, is to cap the ends and come up with a way to secure the two ends of the dash. I called the other day, and

dad has it worked out, just finishing up the fit.

Once the ends are capped, I want to get

started on the middle console. I have been thinking about it for some time, and once I get free to go down to the shop, I

can lay out all the pieces that go in the console and get it's final dimensions. We don't have tons of space, but

enough to do what I need done. The main point is to keep as much room between the console and seat fronts, and for the foot

area. No one wants to feel cramped in. Also, the design has to incorporate the theme of the car. I want it to look good and

be functional. We will also be designing and installing the roof console, that goes in the middle of the roof, from the front

windshield back about 12 inches. This console will house the rear view mirror and the overhead display.

One great new item I finally got around

to buying was a nice set of cheater lenses for my welding hood. What a difference they make, way better they just wearing

glasses under your hood, these babies are crystal clear and I can now see. I am sure my welding will be much better from here

on out, you can't weld what you can't see!!!

I have been very

busy around my house since the first of the year, I decided to step a little further into the modular world, and build engines

and cylinder heads for others. I really fell in love with this engine and wanted to do more with it. I have been purchasing Teksid Aluminum blocks

and re-building them for re-sale to others. I have also decided to start re-building and modifying cylinder heads for the

modular engines. To help with the job, I purchased a valve seat grinder set-up and a valve face grinder set. This with several

other main tool sets will allow me to re-build and modify both 2, 3 and 4-valve heads. My goal is to simply offer great products

at fair prices, I am only concerned with the 4.6 and 5.4l engines and there heads. I have many neat ideals for these pieces

and have come up with several kits to make them stronger and easier to work on. You can read about them on this site by simply

clicking on the link that takes you to that part of the site.

06-02-08

We have been working on the dash, and the extended portion that spaces the front of the dash approximately 2-1/2" further

back then stock. I decided to add this section to the dash to allow us to install defrost ducts up next to the front window.

The benefits are obvious. Dad and I got the two new sections tach welded in place that spread the dash out. There are compound

type curves involved so the blanks took some time to get right, the welding was as usual, the easy part. The next step in

the dash delama, is to cap the ends and come up with a way to secure the two ends of the dash. I called the other day, and

dad has it worked out, just finishing up the fit.

Once the ends are capped, I want to get

started on the middle console. I have been thinking about it for some time, and once I get free to go down to the shop, I

can lay out all the pieces that go in the console and get it's final dimensions. We don't have tons of space, but

enough to do what I need done. The main point is to keep as much room between the console and seat fronts, and for the foot

area. No one wants to feel cramped in. Also, the design has to incorporate the theme of the car. I want it to look good and

be functional. We will also be designing and installing the roof console, that goes in the middle of the roof, from the front

windshield back about 12 inches. This console will house the rear view mirror and the overhead display.

love with this

engine and wanted to do more with it. I have been purchasing Teksid Aluminum blocks and re-building them for re-sale to others.

I have also decided to start re-building and modifying cylinder heads for the modular engines. To help with the job, I purchased

a valve seat grinder set-up and a valve face grinder set. This with several other main tool sets will allow me to re-build

and modify both 2, 3 and 4-valve heads. My goal is to simply offer great products at fair prices, I am only concerned with

the 4.6 and 5.4l engines and there heads. I have many neat ideals for these pieces and have come up with several kits to make

them stronger and easier to work on. You can read about them on this site by simply clicking on the link that takes you to

that part of the site.

06-02-08

We have been working on the dash, and the extended portion that spaces the front of the dash approximately 2-1/2" further

back then stock. I decided to add this section to the dash to allow us to install defrost ducts up next to the front window.

The benefits are obvious. Dad and I got the two new sections tach welded in place that spread the dash out. There are compound

type curves involved so the blanks took some time to get right, the welding was as usual, the easy part. The next step in

the dash delama, is to cap the ends and come up with a way to secure the two ends of the dash. I called the other day, and

dad has it worked out, just finishing up the fit.

Once the ends are capped, I want to get

started on the middle console. I have been thinking about it for some time, and once I get free to go down to the shop, I

can lay out all the pieces that go in the console and get it's final dimensions. We don't have tons of space, but

enough to do what I need done. The main point is to keep as much room between the console and seat fronts, and for the foot

area. No one wants to feel cramped in. Also, the design has to incorporate the theme of the car. I want it to look good and

be functional. We will also be designing and installing the roof console, that goes in the middle of the roof, from the front

windshield back about 12 inches. This console will house the rear view mirror and the overhead display.

06-10-08

Wow, I have to get back into the spirit

of working on the car, being away for a while like I was, makes you rusty.

The dash is

all but finished, at least the modifications we made to it are. It turned out real nice, the section we installed to widen

it 2-1/2" looks nice, and Dad came up with a really cool way to cap off the ends and secure it. I removed it and welded

up the back side, just before we sanded down the front and removed 90% of the weld material. We had no warp-age issues to

address, which is good, and the whole thing was a positive experience. It looks right at home installed in the body, but is

different enough to draw attention, sound perfect to me !!.. One feature we worked hard on, was to make it easy to install

and uninstall from the body, and we were successful. Things get much more difficult with a roll cage to build around, but

it is possible to still make things right. It all just takes time and patients.

The defrost ducts,

which were of coarse the reason we added the width to the dash, are in and went fine. We made the openings much larger then

those I have seen, most time others just cut a small 3/8" or 1/2" x 3" opening. I understand why they do this,

but it doesn't serve as a very good defrost duck with this small of an opening, so we cut an almost full width and length

opening in our dash, this way we will get plenty of flow and hopefully will be able to drive in the rain. I am looking for

some type of material to use as a screen, something like a heavy stainless steel material that is woven, think HD screen or

industrial sifter type material. I'll let you know when I find something. We have this option because our dash is wider.

One item I got going was the door bars and seat back bar. These items have to be removable, because

they would severely limit the inside room and access, but are necessary for competition. In order to make things as easy and

nice as possible, I am using what is called a door bar kit. These items can be purchased from most chassis builders and race

shops, our came from S &W Race Cars and are unique in that they have a center round tube that goes through the roll cage

and gets welded in place. This tube serves as a stiffener and after welding, replenishes the strength of the roll cage, were

others simply leave a hole. The hole is there for the attachment to the roll cage, so the door bars or rear seat back bar

can be removed or installed quickly and easily, by simply installing a bolt or quick release pin. This tube they sell with

there door bar kits, serves to restore the integrity of the roll cage, where simply drilling a 3/4" hole into the 1-5/8"

tube would severely limit it's strength. I did modify our door bar kits to accommodate our needs, the normal way to mount

them would require a stub of the same diameter tubing be welded to the main structure or roll cage. This stub which would

have to be at least 3" in length, would serve as the foundation for the door bar, but because I did not want anything

sticking out from the roll cage that would limit or hinder front or rear seat access, I modified the door bar kits, by drilling

a relief in them so they would now fit over the existing roll cage and mount without the stub. All that was needed was to

drill with a hole saw, roughly the size of the roll cage material which in our case is 1-5/8' tube, a relief in the edge

of the door bar bracket so the new bracket will now wrap around the roll cage bar instead of but up to it. To get this done,

I had to tach weld the two pieces together, when drill a 1/4" pilot hole in the right spot, when follow up with the hole

saw. I'll post some pictures later to clarify the procedure. The benefit of doing it like this is now the door bars and

seat back bar will easily install and remove from the car and there is nothing on the roll cage to snag or poke you as you

enter or exist the car. These kits come in a package of two, with one push-pin connector and one bolt and the four attachment

halves. To do what we did would require three door bar kits, and they run about $39.99 each kit. I have already ordered extra

push-pins to eliminate the use of the bolts, now all the attachment will be by push-pins, which will be much nicer to install

and remove the bars.

Another small projects I worked on was to permanently attach

the running boards. I had attached them with just a few bolts to mock-up the Accusump oil sump, but now I need to go ahead

and install all the hardware and bolt them up for good. First I had to temporarily remove the Accusump to access the area.

Next the running board metal braces we painted to match the frame were installed, these I drilled out to accept a 3/8"

bolt, and installed with all stainless steel hardware. They have one 3/8" x 1" bolt that mount to the bottom of

the frame, and then another 3/8" x 2" bolt that mounts to the running boards, in a double sheer orientation that

really adds some strength to the set-up. The rest of the running board mounting bolts simply attach to the side of the frame,

there are three bolts that support each brace and four bolts that attach to the sides, that makes 14 3/8" bolts hold

each running board on....I don't think their going any place!.! I was simply amazed that everything aligned, I had been

worried that there would be alignment issues but that wasn't even an issue, they bolted right up, I only had to use a

tapered alignment pin to bring everything together, wow what a great day!!! Of-coarse I could not step on the newly installed

running boards, but I did pull down on them and they seemed to be very stout. I was worried because we had boxed the frame

rails, and before I did that, I welded nuts to the back sides of the frame rails so we could attached these running boards,

the problem was there was no way to make-up for anything being off, not even a little bit. We were locked into this location,

and with the running boards being manufactured by one makers and the frame by another, I was really worried about small differences

that would add up against us. I can't tell you how relived I was to see those running boards on and fitting like they

should.