The Supercharger System

The Supercharger Assembly

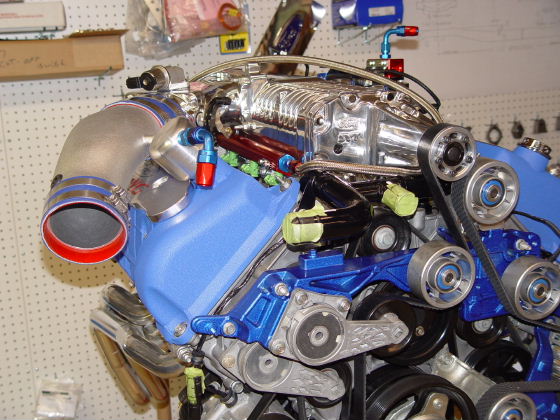

Above: Who doesn't have a soft spot for a V-8 with a Supercharger!!!

The most obvious part on the whole Engine, is,.... yes

you guessed it,.... the Supercharger. Just the look of it sends chills down

the performance minded guy’s spine,,,This is the main difference between the 03-04 Cobra and the rest of the Cobra family.

Of-coarse, by now you have learned that there are many differences that make the 03-04 Cobra special, it’s just this

one piece tells the world who it is and what it can do!

The Supercharger

is relatively a easy piece to get, there are many on E-Bay to purchase, every time I visit the site. The main problem, is

trying to purchase a good, useable, and complete piece....that’s the difficult part. These Superchargers

are still available from Ford, and while they

are very expensive, listing in the $12-1300.00 range, they are useable from the get go. The units on E-bay, at least the majority,

have to be rebuilt before they can be re-used. Yes, the adds might say different, but any Supercharger

with that many miles will need rebuilding.....Period....so make sure you budget for it. Yes you could bolt the used piece

onto your new Engine and it will work, meaning it will turn and might even produce some boost, But it will not produce the

right amount of boost or power a new unit, or re-built unit will. You will be less then impressed with your new Engine, to

say the least. The rebuild process is not that complicated, at least not if the core is still useable. A good company like

Stegmieers, will rebuilt the front drive and re-coat the rotor tips to bring the Supercharger back to like new performance.

They can also Port the Blower for even better performance, as well as Polish the blower

for out standing looks. I have used there services and whole heartedly endorse them.

The

Blower sit on top of the Lower Intake Manifold, and is held there by 10 bolts. Between the Manifold

and the Blower is a special gasket, who’s purpose is to seal the two piece against leaks. This gasket

is always replaced when the blower is separated....no exceptions. It is a very thin metal gasket that has a raised bead all

the way around the gasket and this bead gets flattened when the two are tightened down against one another.

The bottom line is you can buy new and bolt it on, or you can buy used and send it out for a re-build, then bolt

it on. The choice is yours to make, just be sure to know the options and budget accordingly.

Supercharger Assembly

2R3V-6F066

Accelerator Cable Bracket

This small

bracket sits on the passenger side of the Supercharger assembly, and is used to secure the end of the accelerator

cable. I have never seen one of these for sale on E-bay and would advise to just purchase it from Ford, they are not expensive.

Accelerator Cable Bracket

2R3V-9726

Lower Intake Manifold

Above: The Lower Intake Manifold

is a huge piece, and is really something that doesn't normally wear. This is a shot of a new one which will set

you back about $700.00, while Ford still

sells these, they are sometimes listed on E-Bay.

The Lower Intake Manifold is the part the Blower sits on and is bolted

to. This part is very large and is made form Cast Aluminum. While very protected, you have to make sure the

sealing surfaces are OK, and that the bottom of the Intake Manifold is not damaged.

While it is rare, I have seen several Engines where a Rod has let go, taking the block and Intake Manifold with it. This is

just something to check. These are also on the rare parts watch list, and when found always bring top dollar. It’s a

good ideal to buy one anytime you find one at a reasonable price, regardless of weather you plan to build your own "Terminator" Engine or not, they are money in the bank. The Intake

Manifold requires 2-gaskets that seal the passage from the Heads to the Intake

Manifold, and always start with new gaskets. There are 10-Mounting Bolts that secure the supercharger to the

Manifold and another 10-Mounting Bolts that secure the Intake Manifold to the

Heads.

lower Intake Manifold

2R3Z-9J447

Manifold Mounting Bolts (10 Req’d)

Supercharger Charged Air Cooling System

This is a Sub-System of the Supercharger system, and we

will examine this system at a higher degree. The Sub-System is made up of the following parts:

The Inter-Cooler or Charge Air Cooler

The Inter-Cooler Tube Assembly

The De-Gas Bottle

Water Pump

System Plumbing

Front Mounted Cooler

We have already talked about the Charge

Air Cooler or Inter-Cooler as it is known by most. This assembly also includes the Coolant Intake Manifold

and it's gasket. This group of parts consist of the Manifold, 2-small tubes, each

with O-Rings attached to them, and a Gasket. This group of parts has the duty of allowing

coolant to pass into and from the Inter-Cooler without allowing a leak of coolant or air. The Coolant Intake

Manifold, it's gasket and Twin-Tube assembly are very hard items to find used. If you do find these, make

sure the unit is complete, as they are also expensive and hard to get from Ford.

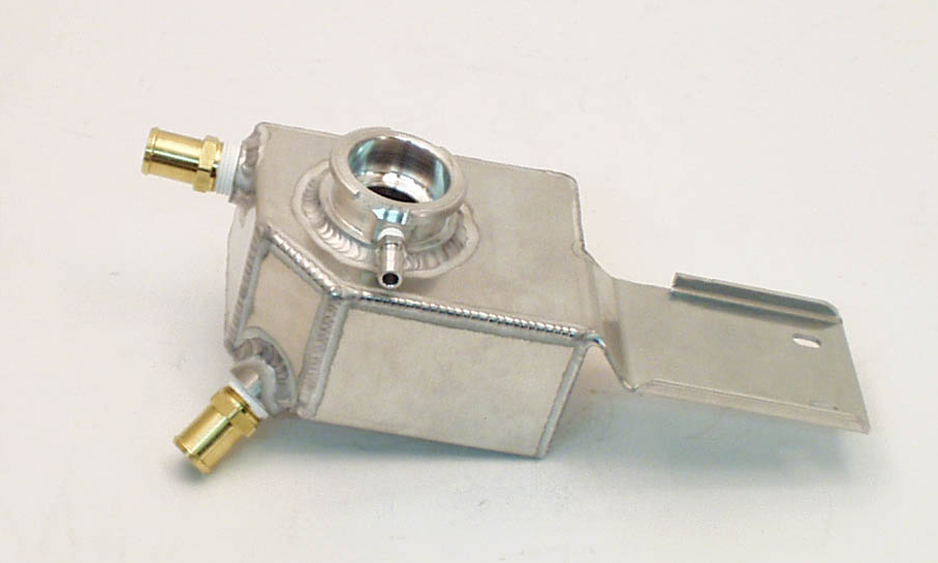

De-Gas Bottle

Above: This is the Canton De-Gas Bottle,

while made completely from Aluminum it can be polished fro a incredible shine. The Factoy piece is plastic and fairly easy

to come by.

The De-Gas Bottle has the responsibility of allowing

traped system air to escape and allowing the owner to re-fill the system with clean freash coolant. The original system

uses a plastic De-Gas Bottle which can be replaced by a Canton Aluminum unit pictured. I have seen

this item on E-Bay cheap, but not many of them. The Canton unit is readialy available and can be polish to a rich luster.

Make sure the De-Gas Bottle is locate at the highhest point in the system, and remember, you have to be abile

to access it for system replinishment.

Front

Mounted Cooler

The Ford

unit mounts in the front fashia, behind the bumper cover. There are stock replacement pieces and several high capacity

units out there for sale. I would consider a higher capacity unit way before I purchased stock unit from the factory.

For those installing this unit in a Hot Rod or Street Rod, you may ellect to not use the De-Gas Bottle or

Front Mounted Cooler from Ford, and instead use a

small Radiator. I have used small Motorcycle Radiators or even small

Car Radiators from Honda to serve as both Cooler and Filler piece.

The main thing is, you have to get the Cooler into the air flow, in crowded locatuion you might think about

using a Electric Fan mounted to the Cooler to draw additional air flow. If placed right, a small radiator

can serve as cooler, de-gas bottle and filler.

Electric

Water Pump

The Water Or Coolant Pump is a seperate

and dedicated part that only serves the Intake Charge Cooling System. This Pump is

manufactured by Bosch and opperates on standard 12 Volts Electric. It is controlled by a Coolant

Temp Sensor that senses Inter-Cooler Coolant temps and switches on or off independently of other vehicle functions.

This is a very popular item on E-Bay and generally sell for $90-100.00. Again there is no need to use a old Pump.

Twin Tube Assembly

and other

Cooling System Hoses

The Twin-Tube Assembly is located

in the passenger side front of the Engine. It takes both incomming and out going coolant down the side of the engine

to where it will connect with the System Hoses. The Assembly keeps the coolant protected

and well dressed. I have many times abandoned this assembly and simply attached my Performance Hoses

right at the Coolant Manifold. This elliminates a lot of engine cluter and keeps the hose connections

to a minimum. You will have one hose that runs from the outlet side of the Manifold to the De-Gas Bottle,

or Radiator (depends on your arangemnt) then one hose from the De-Gas Bottle to the Front

Mounted Cooler. Another hose from the Front Mounted Cooler to the Coolant Pump,

then another hose from the Coolant Pump to the Inlet side of the Manifold. While the

Twin-Tube Assembly has it place, especially on a stock vehicle, it also adds many un-neccessary connections.

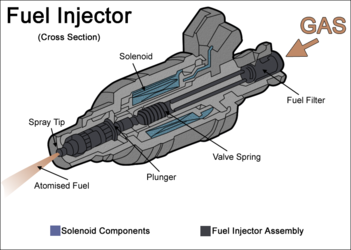

Fuel Injectors

Above: This display will help list the many working parts of a modern Fuel

Injector. The (Green) Ford

Fuel Injectors are the popular replacement for the standard (Blue) Fuel

Injectors that come with the stock 03-04 Cobra Engine.

Above: This display will help list the many working parts of a modern Fuel

Injector. The (Green) Ford

Fuel Injectors are the popular replacement for the standard (Blue) Fuel

Injectors that come with the stock 03-04 Cobra Engine.

The

Fuel Injectors are another item that is specific to the 03-04 Cobra Engine.

They are 39lb/hr rated Fuel Injectors(Blue in Color) that produce a special

Dual-Pattern Spray Cone. This unique Spray Cone is designed to lower emissions and help

with Fuel Economy, by directing the fuel spray pattern towards the back of the Intake Valves. This is another item that is

normally tough to find on E-bay, but I have seen them from time to time. The popular route is to abandon the stock Fuel Injectors in favor of some Ford 42lb/hr

Fuel Injectors. These do not have the Emissions Fuel Spray Pattern,

and make considerably more power then the stock units. Since the stock Injectors

are fairly rare, the performance Injectors are only slightly higher then new

stock units, and make sensible new replacements. I have always replaced the 39lb/hr injectors with the newer 42lb/hr units.

You will have to modify the EEC or Computer fueling tables with the new 42 lb Injectors,

which isn’t a big deal.

I would never use old, high milage Injectors

on a new Engine, it makes no sense. Fuel Injectors have a small O-Ring top and

bottom to seal them, make sure your Injectors have this item and that it’s

in good shape.

Fuel Injector

2R3V-9F593

Fuel

Injector Supply Manifold

Or

Fuel Injector Rails

Above Top: This is the Stock and very restrictive Fuel Injector

Supply Manifold. Above: This is the good looking Aeromotive Fuel Rail

The Fuel Injector Supply Manifold used

on the stock 03-04 Cobra Engine is very restrictive. It consist of a very small steel line, one for each side, connected by

a rubber hose. This is one item I would throw in the trash, and replace if I was building a 03-04 Cobra Engine and had this

piece. In it’s place I would install a nice Aluminum Fuel Rail, like the

ones Aeromotive or similar manufactures make. These not only look nicer,

but flow tons more fuel and will really wake-up that Cobra Engine. The stock 03-04 Cobra uses what is known

as a Non-Return style Fuel System. This means the Fuel

drawn from the Fuel Tank is on a one way trip to the Fuel Injectors,

the system uses a Pressure Transducer and Computer to very Fuel Pump output to meet Engine

demands, and the Fuel will wait till the Engine needs it, resting inside the Fuel System Lines, Rails and

Filter. On a Return Style System, the Fuel is drawn

from the Fuel Tank and sent directly to the Fuel Rail, there the Engine uses a portion of

the Fuel and what is not used is sent back to the Fuel Tank. In this system the Fuel

Pump is always running at full speed, and the Fuel Pressure Regulator is responsible for determining

how much Fuel gets returned to the Fuel Tank. There are pro’s and con’s to both

systems, but it is generally agreed on that the Return Style Fuel System is

more High Performance Oriented and makes more Power.

I have used with exceptional results, the

Kenny Bell Adjust-A-Pump, Fuel Pump Booster. The system uses a transformer

to raise secondary voltage to the Fuel Pump, which makes the Fuel Pump, Pump faster for

more Volume and Fuel Pressure. This System works great and only increases the Fuel Pump Output

when needed, like when Boost pressure is High.

Fuel

Injector Supply Manifold

2R3V-9F792

Fuel Pulse Damper

2R3V-9C986

Vacuum Activator Valve

This piece,

the Vacuum Activator Valve, Is located on the drivers side of the Blower up

on top. It is there to protect the Blower from back fires and sudden pressure spikes. It also allows the blower to "Free

Wheel" when load is low, saving some much needed fuel for better Fuel Economy. This Valve is usually

included with the Blower, but watch for broken or cracked Valves, as the unit is made of plastic and often gets damaged in

transit. RPM Outlet, a great source for Cobra Parts, has a free diagram

on how you can modify the Valve for better performance. You can check them out at: http://www.rpmoutlet.com/boost%20bypassc.htm

While there check out there great selection of 03-04 Cobra parts, not only are

they one of the Cheapest part sources around, but they have excellent customer service!! I have used them many times with

great results.

The Activator Valve mounts to the

Vacuum Accessory Bracket along with the Manifold

Absolute Pressure Sensor, Differential Pressure Feedback EGR System, and Exhaust

Gas Recirculation Vacuum Regulator. Most eliminate the EGR System when

they build one of these Engines, but you may or may not decided to keep it in tact. If you do you will need the Associated

parts for the EGR System which I will list below.

Vacuum Activator Valve 2R3V_6F089

Bolts (2 Req’d)

2R3V-N605892

Exhaust Gas Recirculation Tube 2R3V-9D477

EGR Valve 2R3V-9D475

Manifold Absolute Pressure Sensor

Differential Pressure Feedback EGR System 2R3V-9J460

EGR Vacuum Regulator 2R3V-9J472

Throttle

Body

and

Spacer

Tube

and

Spacer

Tube

and

Spacer

Tube

The Throttle

Body is located on the Passenger Side top of Engine, it is connected to the Blower by the Spacer

Tube. The Throttle Body is designed

to Limit the intake of air, and it does so by opening or closing it’s two large intake plates or more commonly known

as "Butterflies". Attached to the Throttle

Body are the TPS or Throttle Position Switch and

IACV or Idle Air Control Valve. The TPS allows the EEC or Computer

to know the position of the throttle body butterflies, and the IACV is adjusted

by the EEC or Computer to maintain a steady and smooth Idle.

The Throttle

Body and it’s Spacer are very popular items on E-Bay,

and for good reason, most replace the factory units with better performing pieces from makers like BBK

and Accufab. There produces have larger openings for more

volume and come polished or chromed, for supper good looks. If I was pressed to purchase a new unit, it would be one from

the aftermarket, and not a stock ford part.

Idle Air Control Valve

2R3V-9F715

Idle Air Control valve Gasket

IACV

Mounting Screws

Spacer Assembly

2R3V-9P697

Throttle Body Gasket

2R3V-9E936

Throttle Body

2R3V-9E926

Bolts (4 Req’d)

Bolts

(2 Req’d)

Throttle Position Switch

2R3V-9E929

Nuts (4 Req’d)

2R3V-N804178

Studs (4 Req’d)

Spacer

Assembly Gasket